- Home

- Our assortment

- Flexhal

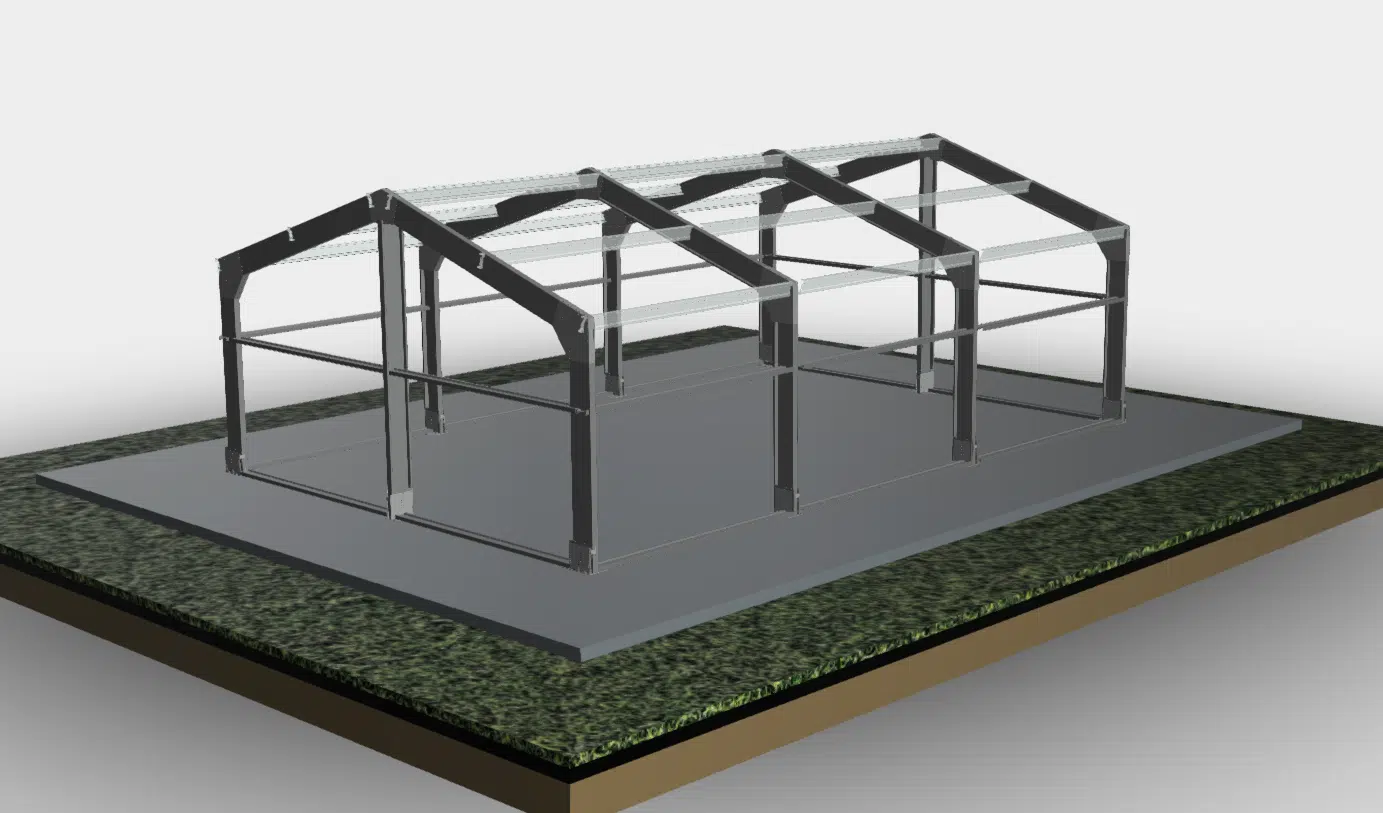

Flexhal

Semi-permanent steel hall with the look of a permanent industrial building

10x30x3 m — From €50,000 (excl. VAT)

20x40x3 m — From €80,000 (excl. VAT)

Prices based on a steel structure, including RAL 7016 sandwich wall and roof panels and RAL 9005 metal flashings (excluding doors and windows).

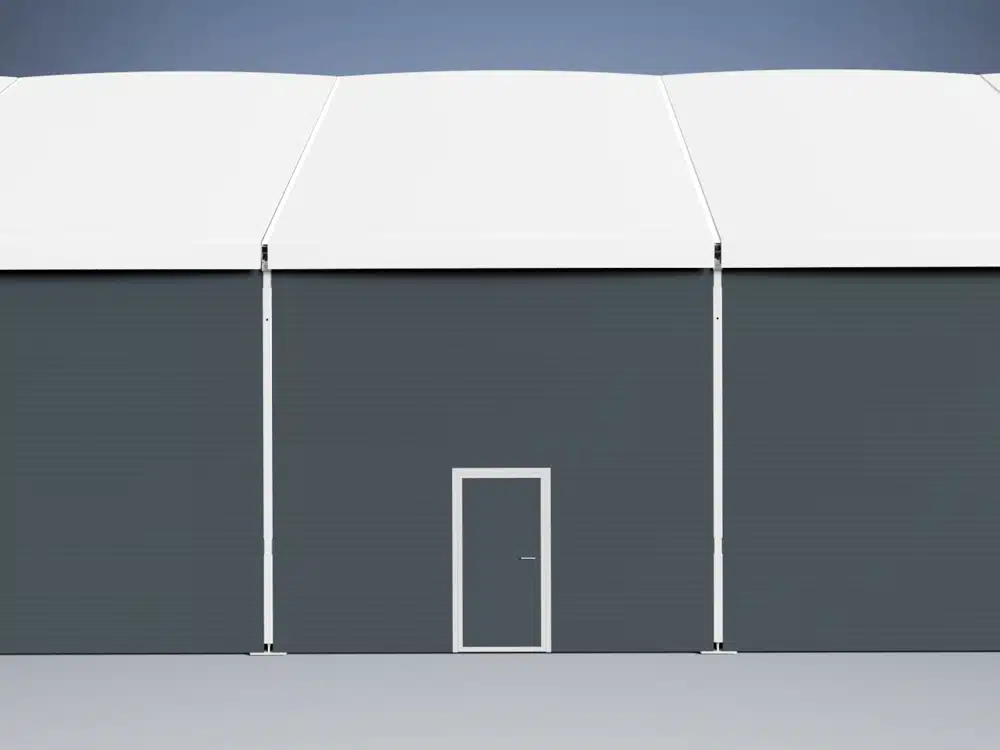

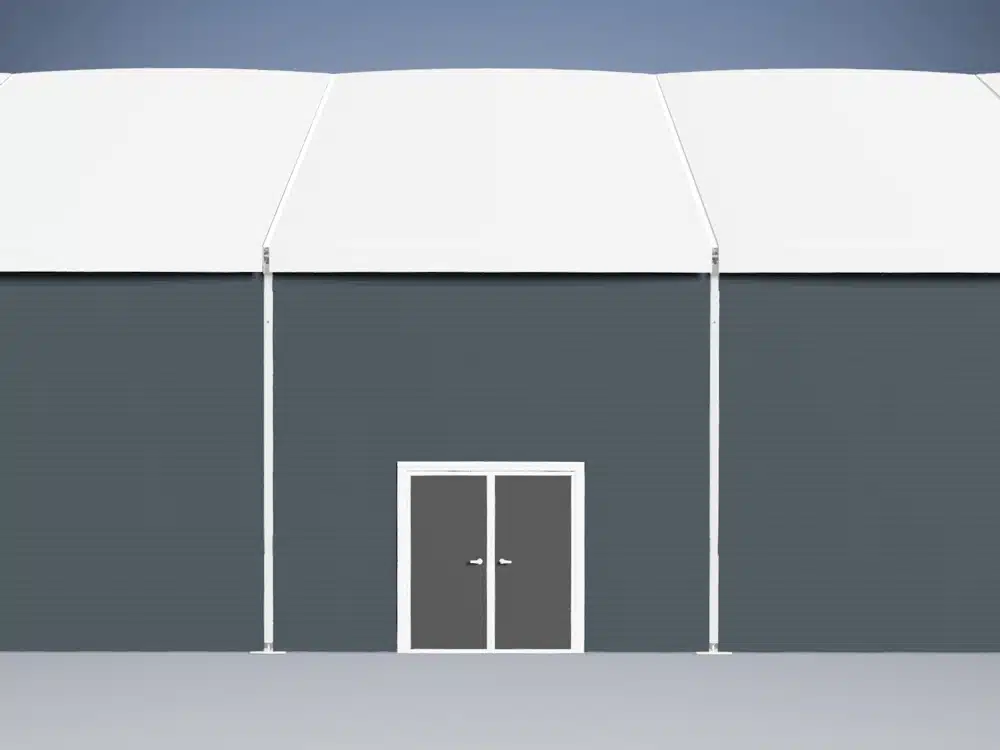

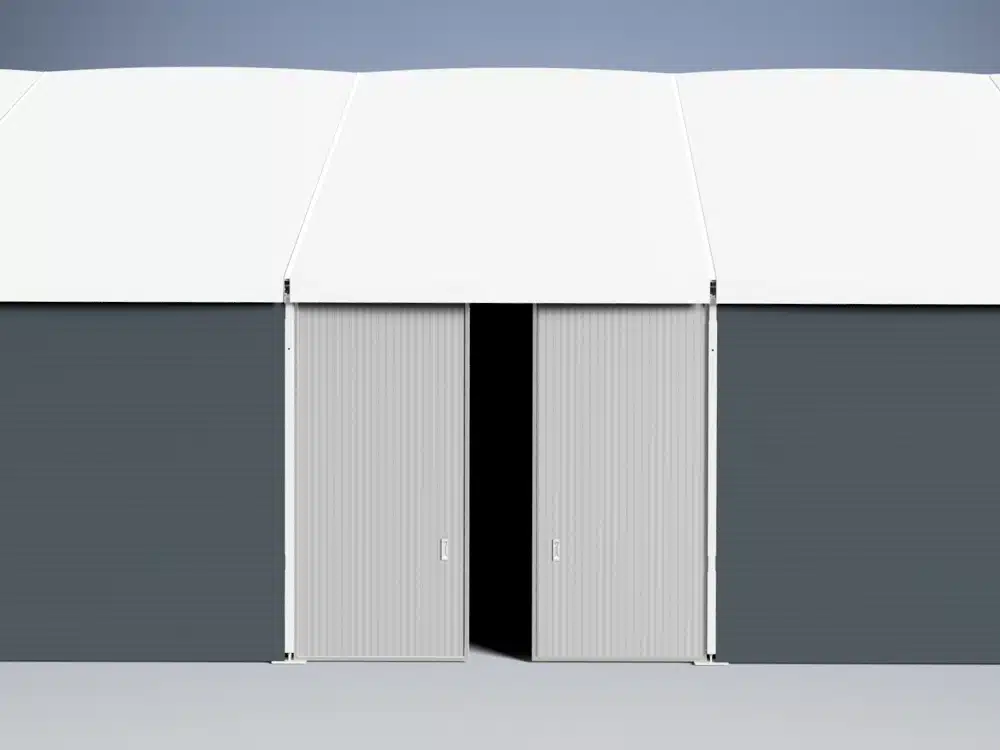

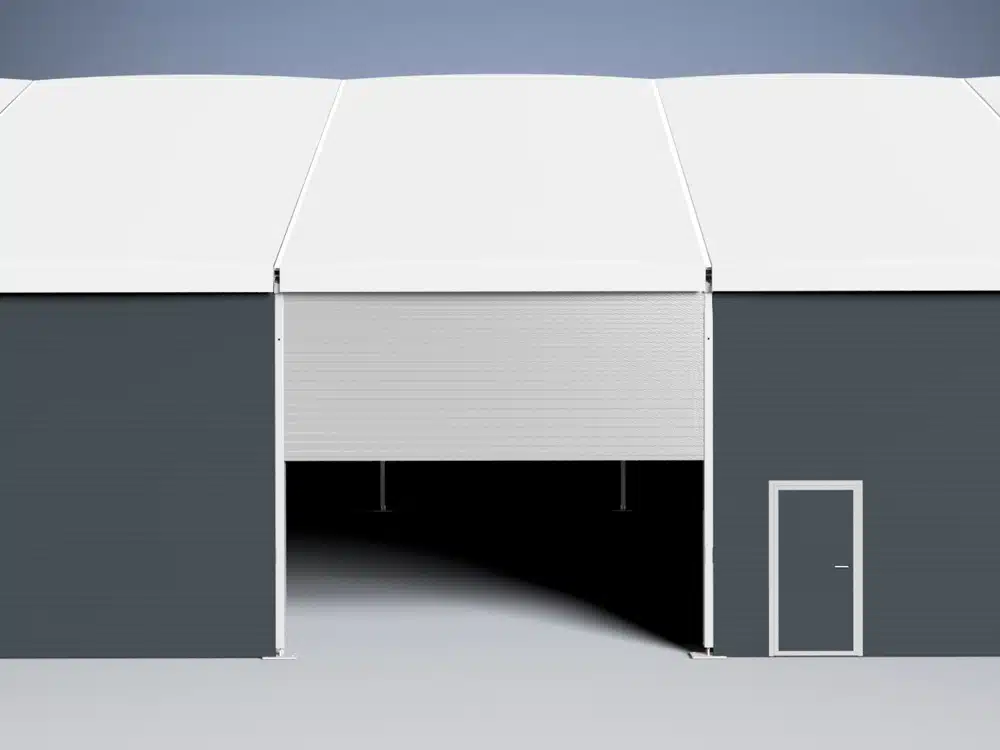

The Flexhal by Tent Trading is our most robust solution, closely matching the quality of a permanent building while retaining the flexibility of a modular system. This steel structure is designed for businesses seeking a solid appearance and high-performance insulation. The Flexhal is supplied as standard with 60 mm PIR sandwich panels for both walls and roof, finished in the modern colour RAL 7016 (anthracite).

We supply the Flexhal as a complete construction kit. Due to the weight and complexity of the steel trusses, installation must be carried out by a specialised contractor (such as a tent rental company or a construction firm experienced in steel structures). If you do not have this expertise in-house, we can connect you with our network of installation partners specialised in our steel systems.

What can you use a Flexhal for?

Spacious and tall industrial hall

The Flexhal is perfect for businesses needing a combination of office and workshop space. With side heights of up to 6 meters, it’s easy to create a second floor, allowing you to divide the space efficiently. The sandwich panels ensure a well-insulated working environment.

Temporary shelter or facility

The Flexhal is an excellent choice for temporary insulated buildings during emergencies, renovations, or seasonal peaks. It’s quick to install and provides a safe, insulated and comfortable environment thanks to its sturdy design. A reliable and flexible solution.

Retail space & showroom

The Flexhal works well as a shop or showroom. The insulated sandwich panels help maintain a pleasant indoor temperature year-round. The flexible interior allows you to design the space exactly to your liking.

Discover the Flexhal in 90 seconds

Curious how the Flexhal is assembled and what this semi-permanent steel hall can offer?

In this 1:30 minute animation, you’ll see step by step how the structure works and why the Flexhal is the ideal solution for storage, production, or business space.

- 60 mm PIR sandwich panels (11.52 kg/m²) | Rc-value 2.76 m²K/W | Fire class B-s2,d0

- 80 mm PIR sandwich panels (12.28 kg/m²) | Rc-value 3.85 m²K/W | Fire class B-s2,d0

- 100 mm PIR sandwich panels (13.04 kg/m²) | Rc-value 4.81 m²K/W | Fire class B-s2,d0

- 120 mm PIR sandwich panels (13.78 kg/m²) | Rc-value 5.76 m²K/W | Fire class B-s2,d0

- 150 mm PIR sandwich panels (14.94 kg/m²) | Rc-value 7.18 m²K/W | Fire class B-s2,d0

- 60 mm Rockwool sandwich panels (16.58 kg/m²) | Rc-value 1.38 m²K/W | Fire class A2-s1,d0

- 80 mm Rockwool sandwich panels (18.64 kg/m²) | Rc-value 1.83 m²K/W | Fire class A2-s1,d0

- 100 mm Rockwool sandwich panels (20.64 kg/m²) | Rc-value 2.29 m²K/W | Fire class A2-s1,d0

- 120 mm Rockwool sandwich panels (22.64 kg/m²) | Rc-value 2.74 m²K/W | Fire class A2-s1,d0

- 150 mm Rockwool sandwich panels (25.57 kg/m²) | Rc-value 3.42 m²K/W | Fire class A2-s1,d0

- 60 mm PIR sandwich panels (11.52 kg/m²) | Rc-value 2.76 m²K/W | Fire class B-s2,d0

- 80 mm PIR sandwich panels (12.28 kg/m²) | Rc-value 3.85 m²K/W | Fire class B-s2,d0

- 100 mm PIR sandwich panels (13.04 kg/m²) | Rc-value 4.81 m²K/W | Fire class B-s2,d0

- 120 mm PIR sandwich panels (13.78 kg/m²) | Rc-value 5.76 m²K/W | Fire class B-s2,d0

- 150 mm PIR sandwich panels (14.94 kg/m²) | Rc-value 7.18 m²K/W | Fire class B-s2,d0

- 60 mm Rockwool sandwich panels (16.58 kg/m²) | Rc-value 1.38 m²K/W | Fire class A2-s1,d0

- 80 mm Rockwool sandwich panels (18.64 kg/m²) | Rc-value 1.83 m²K/W | Fire class A2-s1,d0

- 100 mm Rockwool sandwich panels (20.64 kg/m²) | Rc-value 2.29 m²K/W | Fire class A2-s1,d0

- 120 mm Rockwool sandwich panels (22.64 kg/m²) | Rc-value 2.74 m²K/W | Fire class A2-s1,d0

- 150 mm Rockwool sandwich panels (25.57 kg/m²) | Rc-value 3.42 m²K/W | Fire class A2-s1,d0

- Flashing | RAL 9005

- Flashing | RAL colour of choice

10 to 30 meters

Unlimited, extendable per 5 meters

4.00 m | 5.00 m | 6.00 m

Standard

Optional

Standard

Optional

Standard

Optional

Cold-rolled | 450 mm C+ profile

Create your ideal

Flexhal here!

Got to Flexhal configurator

Calculations & Safety

At Tent Trading, safety comes first. All of our structures are designed by experienced engineers and checked by certified structural engineers. Each Flexhal comes with detailed structural calculations as standard. We also support you with the documents needed for a smooth permit application process.

Want to know more? Don’t hesitate to contact us!

Need help?

My name is Erik, I’m Sales Manager at Tent Trading. Would you like personal advice on a Flexhal that suits your company? Feel free to contact me or request a free quote right away!

Need help?

My name is Erik, I’m Sales Manager at Tent Trading. Would you like personal advice on a Flexhal that suits your company? Feel free to contact me or request a free quote right away!